Horizontal Line

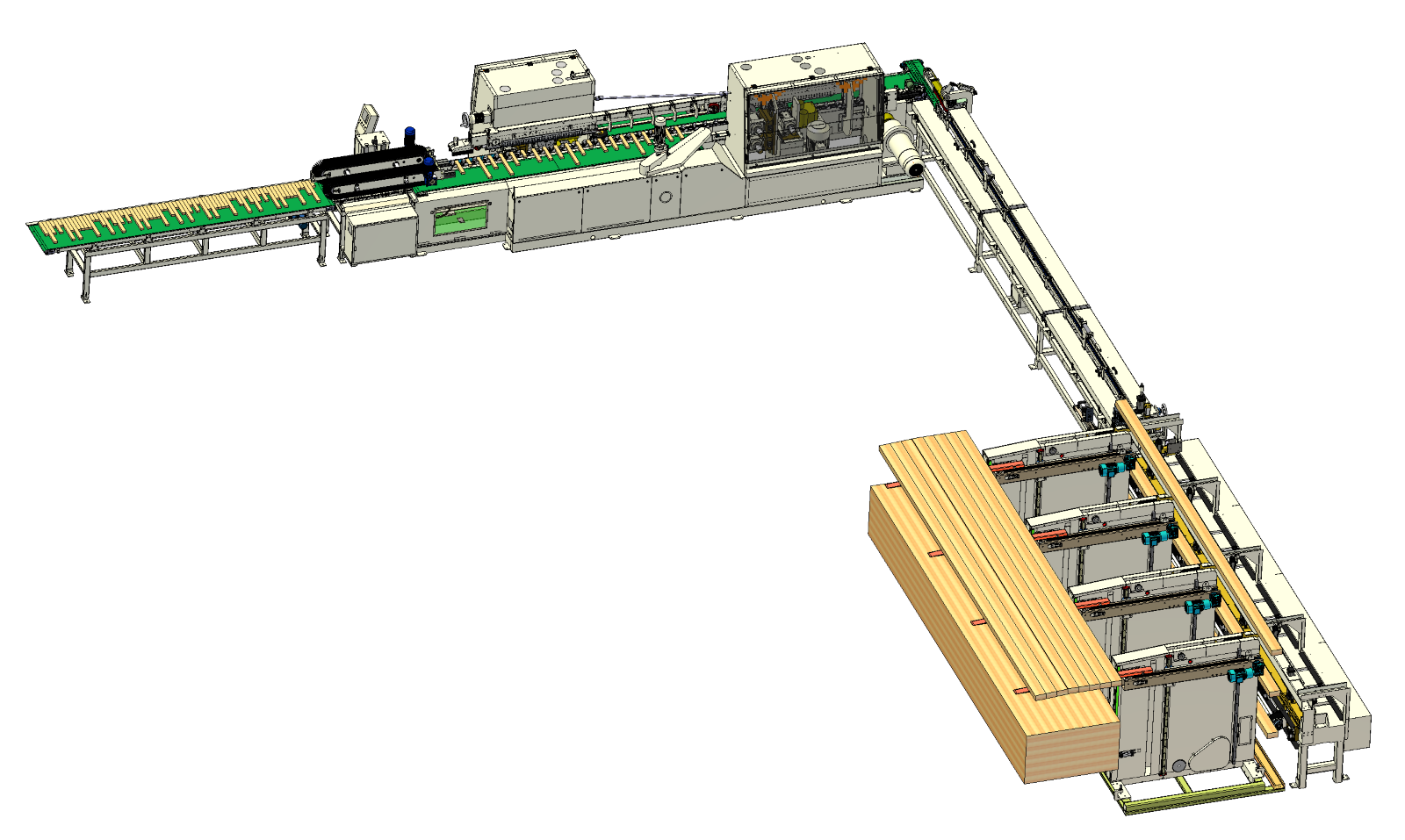

Horizontal Finger Joint System -H Series

- Up to 200 lugs per min finger joint system.

- Main control interface to operates and adjustment while in production.

- High reliability and operator safety design.

- This line can be upgrade with fully automatic infeed line and outfeed stacker machine.

- Trim saver as an option.

High performance finger joint system

The KTCC H Series Horizontal Finger Joint Machine is designed for high-efficiency wood joining, featuring high-speed processing and precise control technology. It ensures stable joining of various wood types and is widely used in furniture, flooring, and woodworking production lines. Its modular design allows easy maintenance and upgrades, guaranteeing long-term reliable operation.

Heavy-duty finger joint system

The H Series Horizontal Finger Joint Machine features a heavy-duty mechanical structure, with a robust frame and high-strength steel components at critical points. It can withstand prolonged high-load operation, ensuring joint precision and production stability. Whether processing long timber or large panels, it maintains accurate jointing and enhances line efficiency and reliability.