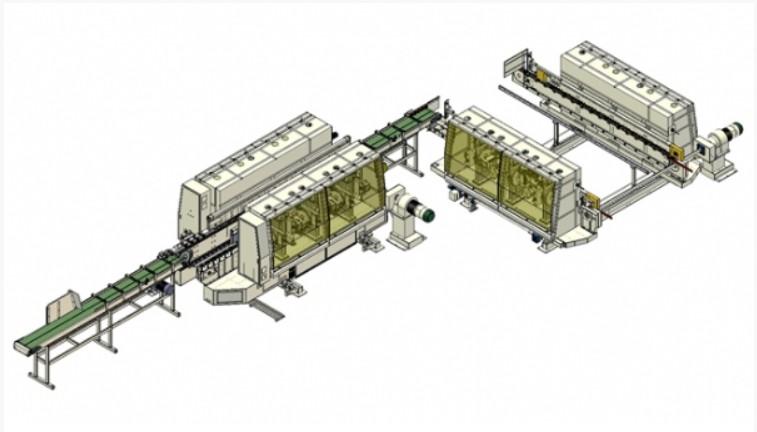

Flooring Line

KDET-PL

A combination production line of one longitudinal and one transverse to processing all 4 sides of each element. An in-feeder and corner feeder connected both double end tenoner to become fully automatic production line. Great accuracy and minimum processing width 75mm also achieved. Maximum processing speed up to 60m/min.

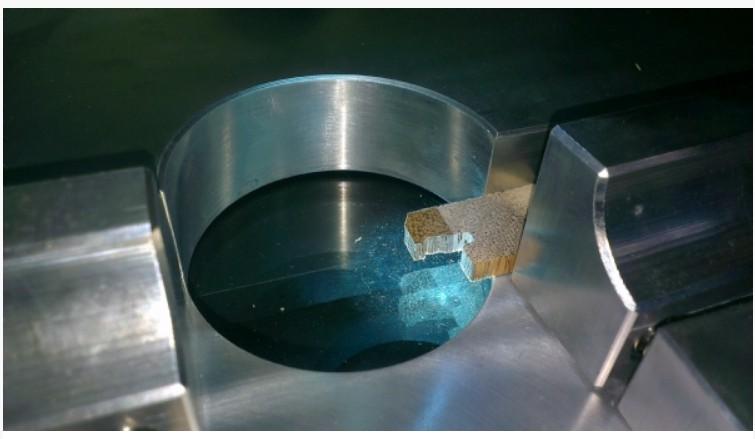

Model

KDET-V

Min. working width

65mm / 90mm

Working thickness

60m/min

Number of trimming motor

4 heads / 6 heads / 8 heads / 10 heads or more

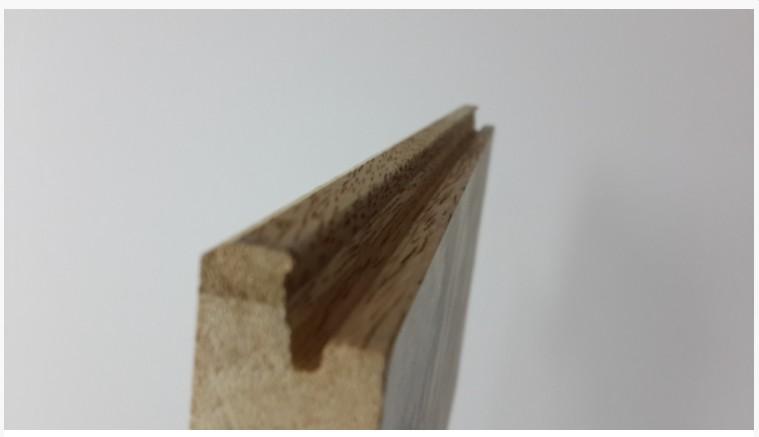

Model

KDET

Min. working width

180mm

Working thickness

8mm~60mm

Max. working speed

35m/min (Optional 60m/min)

Distance of DOG (Standard)

400mm

Number of trimming motor

4 heads / 6 heads / 8 heads / 10 heads and more